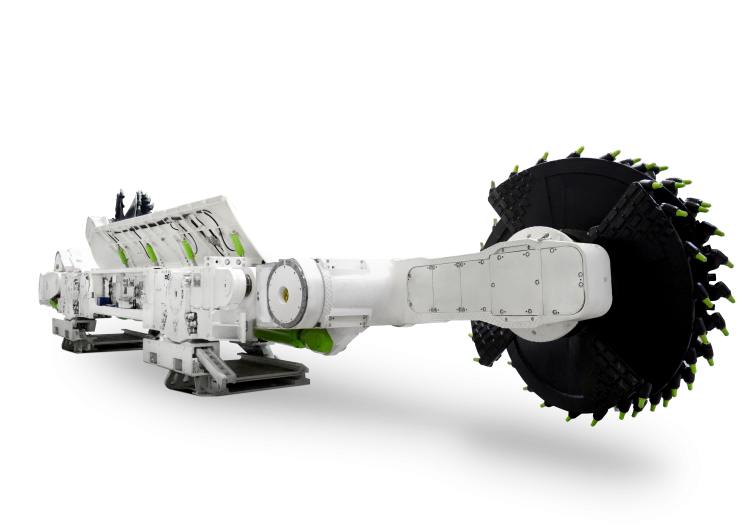

FS 800

The FS 800 is a new generation longwall shearer, which was developed as a result of a combination of experience, advanced technical solutions, modern technologies and the highest quality materials.

Through the modular structure, the transport dimensions have been minimised, but this did not reduce the enormous capabilities of the shearer and its ability to work in high seams (cutting height up to 6 m). This machine is a shallow-web shearer, it works with armoured conveyors of 900m to 1,200m wide equipped with Eicotrack, Megatrac® or Gigatrack chainless haulage systems.

The haulage system structure allows to obtain various shearer heights without changing the hauling (carriage) bodies. The shearer loader has been designed in the Industry 4.0 standard, with functions of advanced parameter diagnostics and full monitoring of the machine operation on a mine surface. It is characterised by high efficiency, reliability, ease of use and operation. The FS 800 can be provided in the along with additional equipment enabling operation in an automatic or remote cycle. The shearer is adapted to work in underground mines of class “a”, “b”, “c” methane explosion hazard and class “A” and “B” coal dust explosion hazard.

- modern solutions for machine operation safety

- advanced self-diagnostics of shearer subassemblies

- easy adaptation of the shearer to work with various types of face conveyors (width from 900 to 1200 mm)

- modular design enabling obtaining various cutting heights and adapting the machine to various types of haulage system

- large area of shearer ground clearance

- modular structure limiting the transport dimensions to 3.2 m

- comfort of mechanical maintenance service (all main units accessible from the gob side)

- two independent hydraulic systems with functional distribution to the left and right side

- automatic lubrication system of the shearer key components (nodes)

- the ability to work in the mode of mutual availability of hydraulic systems

- possibility to install the loader

- possibility to install a universal lump breaker (crusher)

- modular design of electrical equipment

- comfort of electrical maintenance service (all main units accessible from the gob side)

- converter power-electronic system ensuring return of energy to the power network

- the ability of the haulage system to work in a single-motor mode

- application of flameproof connectors for power and signal circuits

- control system in the Industry 4.0 standard

- large, easy-to-read LCD display

- shearer data transmission in the Ethernet standard

- data readout and the shearer parametrization in the Wi-Fi standard

- continuous monitoring and display of basic shearer operational parameters on remote controls and local system panels

- in-wall shearer positioning system

- Memory Cut system

- vision system

- methane concentration measurement system

- working platforms

- remote control system from the longwall centre or maingate

| maximum cutting height [mm] | 6 000 |

| horizontal centre-to-centre distance between cutting drums [mm] | 14 750 |

| distance between driving wheel axes/centres [mm] | 5 960 |

| machine body height [mm] | 1 500 - 1900 |

| undercut [mm] | 300 |

Additional parameters

| supply voltage [V] | 3 300 |

| total installed power [kW] | 2 435 |

| cutting drum motor power[kW] | 500 - 950 |

| cutting drum diameters [mm] | 1 800 – 3 000 |

| web [mm] | 800 – 1 200 |

| arms type | FRA 800 |

| power of the electric haulage drive motor [kW] | 2 x 150 |

| power of the electric motor of the hydraulic pump unit [kW] | 2 x 30 |

| allowable longitudinal inclination gradient [°] | ± 35 |

| allowable transverse inclination gradient upwards[°] | 25 |

| allowable transverse inclination gradient downwards[°] | 15 |

| pulling force [kN] | 2 x 525 |

| haulage speed [m/min] | 0 - 39 |

| maximum weight [t] | 98 |