Material transport devices

FAMUR is an experienced and respected manufacturer of auxiliary transport equipment and systems, intended for the haulage and handling of materials and for transporting people. All material transport devices offered by FAMUR are adapted to be used in areas with methane and coal dust explosion hazards.

Hydraulic mobile hoist WJ-Z, WJ-ZA

The latest mobile hoist with a lifting capacity of 40 kN. It is characterized by a simplified construction of the winch, reduced weight and small dimensions.

Mobile hoist WJ-S

Standard mobile hoist with hydraulic drive. It is characterized by an extremely low “dead zone” of 345 mm. In addition to the standard version with a load capacity of 40 kN, versions with a hook block with a load capacity of 63 and 80 kN are also available.

Bearing beam BN-S

The BN-S bearing beam is designed for transporting materials by monorail with cable or self-propelled drive. It is equipped with two chain winches with a hydraulic drive for lifting and lowering the transported materials. BN-S beams have an adjustable spacing of hooks and the ability to lower materials manually.

Modular load-carrying unit ZNMW

The ZNMW load-carrying unit is characterized by a modular structure, enabling its operation in various configurations. By changing the configuration, you can get different load capacities and adapt the set to transport different items. Special cases of system configuration are those adapted to the transport of powered support units. The basic element of the set is a bearing beam with two carrying trolleys with a lifting capacity of 80 kN. By connecting the beams together, a maximum load capacity of 160, 240 or 320 kN can be obtained. Adaptation of the set to the transport of specific materials is provided by the use of additional equipment such as hook blocks, longitudinal beams, girders, traverses, etc.

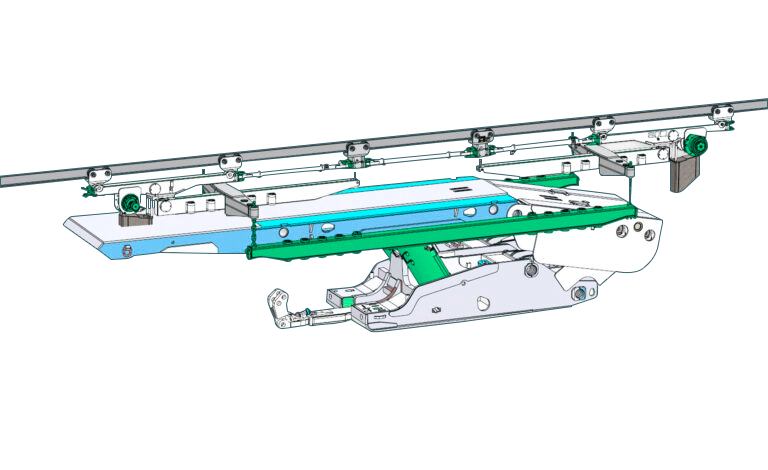

Modular load-carrying unit ZNMW II

The latest ZNMW II transport set is characterized by a modular structure that enables operation in various configurations optimally adapted to the intended transport tasks. The spacing of the carrying trolleys is 2.25 m, which allows operation with maximum load practically on all rail lengths used in mines. An additional advantage is the length compensation system for driving around curves, embedded into the bearing beams.

The basic element of the ZNMW II load-carrying unit are steel bearing beams (modules) equipped with chain hoists for lifting and lowering the transported material. The hoists are hydraulically driven.

Hooks are used to fasten the transported material. In addition to the bearing beams with hoists, the set has additional equipment, such as traverses, load beams, etc. elements that facilitate the loading of the material and the appropriate distribution of the weight of the transported load on the carrying trolleys and the rail route.