KSW-1500EU1

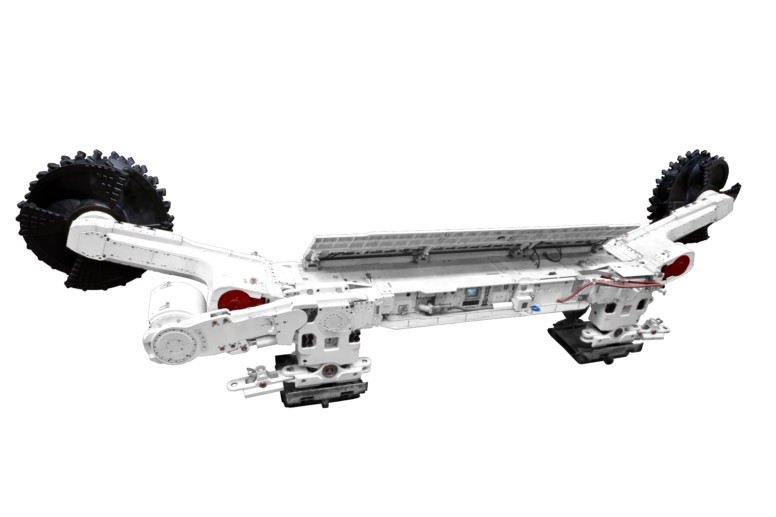

Kombajn ścianowy KSW-1500EU1 to ścianowy kombajn z napędem elektrycznym. Jest to maszyna cechująca się wydajnością, niezawodnością oraz łatwością obsługi i eksploatacji.

Konstrukcja kombajnu dostosowana jest do współpracy z różnymi typami przenośników zgrzebłowych ścianowych o szerokości od 860 do 1100 mm , wyposażonych w bezcięgnowy system posuwu Eicotrack (125 lub 125 mm); Megatrack®(147 mm) lub Gigatrack (151 mm).

Kombajn zostaw zaprojektowany w standardzie przemysłu 4.0; posiada zatem funkcje zaawansowanej diagnostyki parametrów oraz pełnego monitoringu pracy maszyny na powierzchni kopalni. Kombajn KSW-1500EU1 może być dostarczony z dodatkowym wyposażeniem. Kombajn przystosowany do pracy w podziemnych zakładach górniczych klasy “a”; “b”; i “c” niebezpieczeństwa wybuchu metanu oraz klasy A i B zagrożenia wybuchem pyłu węglowego.

- nowoczesne rozwiązania dotyczące bezpieczeństwa obsługi maszyny

- zaawansowana autodiagnostyka podzespołów kombajnu

- łatwość dostosowania kombajnu do współpracy z różnymi typami przenośników ścianowych (szerokość od 900 do 1200 mm)

- konstrukcja umożliwiająca uzyskanie różnych wysokości urabiania oraz dostosowanie maszyny do różnych typów systemu posuwu

- duży prześwit pod kombajnem

- komfort mechanicznej obsługi serwisowej (wszystkie główne zespoły dostępne od strony zawałowej)

- układ automatycznego smarowania kluczowych węzłów kombajnu

- możliwość montażu ładowarki

- mozliwość montażu uniwesalnej kruszarki urobku (kęsów)

- modułowa budowa wyposażenia elektrycznego

- komfort elektrycznej obslugi serwisowej (wszystkie główne zespoły dostępne od strony zawałowej)

- układ energoelektroniczny przemiennika zapewniający zwrot energii do sieci

- możliwość pracy w trybie jednosilnikowym układu posuwu

- system sterowania w standardzie przemysłu 4.0

- duży czytelny wyświetlacz LCD

- transmisja danych z kombajnu w standardzie Ethernet

- odczyt danych i parametryzacja kombajnu w standardzie WiFi

- ciągłe monitorowanie i wyświetlanie podstawowych parametrów pracy kombajnu na pilotach radiowych i pulpitach sterowania lokalnego

- system pozycjonowania kombajnu w ścianie

- system pamięci skrawu

- system wizyjny

- system pomiaru stężenia metanu

- pomosty robocze

- system zdalnego sterowania ze środka ściany lub chodnika przyścianowego

| maksymalna wysokość urabiania [mm] | 5 500 |

| odległość między osiami organów urabiających w poziomie [mm] | 14 800 |

| odległość między osiami kół napędowych [mm] | 6 755 |

| wysokość korpusu maszyny [mm] | 2 495 |

| podcięcie [mm] | min. 250 |

Dodatkowe parametry

| napięcie zasilania [V] | 1 000, 1 140, 3 300 |

| zainstalowana moc całkowita [kW] | 970 – 1 705 |

| moc silnika organu urabiającego [kW] | 350 - 630 |

| średnice organów urabiających [mm] | 1 500 – 2 700 |

| zabiór [mm] | 800 – 1 000 |

| moc silnika elektrycznego napędu posuwu [kW] | 2 x 120 |

| moc silnika elektrycznego zespołu pomp hydraulicznych [kW] | 30 |

| dopuszczalne nachylenie podłużne [°] | ± 45 |

| dopuszczalne nachylenia poprzeczne po wziosie [°] | 20 |

| dopuszczalne nachylenia poprzeczne po upadzie [°] | 15 |

| siła uciągu [kN] | 2 x 640 |

| prędkość posuwu [m/min] | 0 - 27 |

| maksymalna masa kombajnu [t] | ~100 |