Service in grid monitoring area

Following Industry 4.0 trends, we are systematically developing training tools using virtual reality, remote diagnostics and field service smart glasses technology to operate equipment for various industry sectors.

What technologies does the SIGMA room use?

As part of this activity, we developed and implemented a concept to create an innovative SIGMA (Service in Grid Monitoring Area) room. It is an idea based on the use of modern technologies such as Virtual Reality (VR), webex, smart glasses and smart mining. The SIGMA room allows users to collaborate online with customers, provides real-time analysis of machine parameters, and enables users to connect with an operator equipped with field service smart glasses from anywhere in the world. For several months, the SIGMA hall has been hosting training sessions, conferences and meetings with both Polish and foreign customers.

As part of this activity, we developed and implemented a concept to create an innovative SIGMA (Service in Grid Monitoring Area) room. It is an idea based on the use of modern technologies such as Virtual Reality (VR), webex, smart glasses and smart mining. The SIGMA room allows users to collaborate online with customers, provides real-time analysis of machine parameters, and enables users to connect with an operator equipped with field service smart glasses from anywhere in the world. For several months, the SIGMA hall has been hosting training sessions, conferences and meetings with both Polish and foreign customers.

The Service Centre is confidence and reliability

Grzegorz Marcinkowski

Central Service Department Director, Domestic and Export Markets

Contact

Poland and other countries

+48 32 359 67 78

+48 32 359 66 31

Kazakhstan

+7 727 251 3941

+7 727 251 4670

Service support

The Service Center is available to customers 24 hours a day, 7 days a week, 365 days a year. Our specialists have the necessary knowledge and experience to restore the maximum efficiency of machines in the shortest possible time.

The telephone interview and diagnostic analysis conducted during the interview help to assess whether the reported issue can be resolved remotely or whether a qualified service technician should be delegated for this purpose.

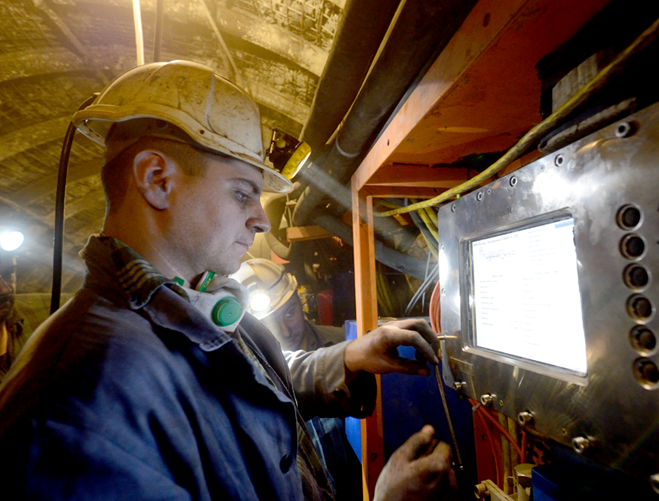

On-line monitoring

The Service Centre applies the latest information technologies that our devices are equipped with. A dedicated software set creates a fully functional tool that enables to visualize the working parameters of the entire technological production process in real time.

Diagnostic data from the machines are sent to the FAMUR premises, where these data are subject to analysis to assess in detail the condition of the equipment in use. The methods used by the Service Centre make it possible to detect damage at a very early stage of propagation, which reduces the risk of the machine’s downtime and related costs.

Direct support at the customer's side

We have dedicated service teams for all product groups offered by the FAMUR. Each of them consists of specialists in the fields of electrical engineering, mechanics, diagnostics and mining. In order to make inspections and remove defects, we send to the customer a service technician whose job is to perform the work efficiently and as quickly as possible.

After warranty customer service

We invite our customers to work with the service staff also after the warranty period. We realise how important it is to eliminate downtimes and to execute production plans.

The Service Centre provides professional assistance in each case – technical consultation, inspections, troubleshooting and delivery of spare parts.

Service tasks

Continuous monitoring of the current state of machines

Immediate reaction to a reported problem

Controlling alarm thresholds of diagnostic systems

Generating periodic and warning reports